Best practices for creating a CNC file

Our best practices guide for creating an high quality CNC file

- Follow the advice at: http://www.shape3d.com/Manuals/Shape3d_Design_Trick_Tip.pdf

- Ensure the nose thickness is at least 5/16” or even slightly thicker – this is a minimum thickness

- Apex point must be at the widest point of the rail on every slice – see image below

- Each slice must have the same number of points as any other slice (we recommend 3 points per slice excluding the default points along the stringer)

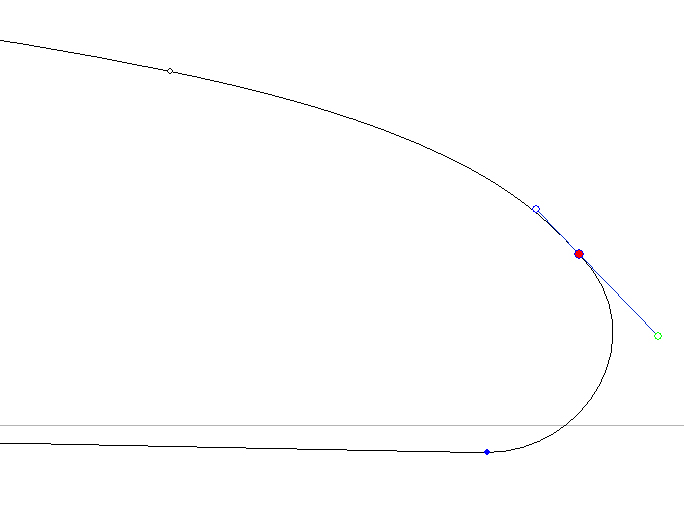

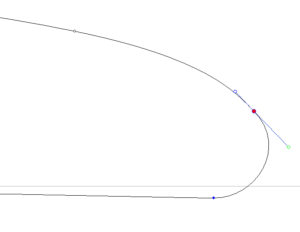

Example of a bad apex on a CNC file – this apex isn’t at the widest point of the rail.

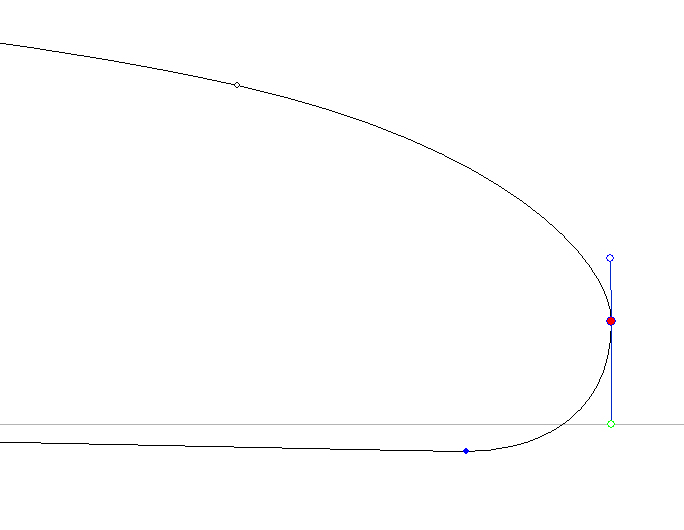

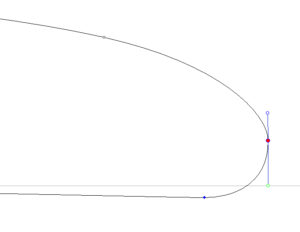

Example of a good apex on a CNC file – the apex is the widest point of the rail.

Please review our other essential reading on CNC pre-shape cutting services that we offer. If you want a more traditional non-software route then consider hand shaping your own board.